Services

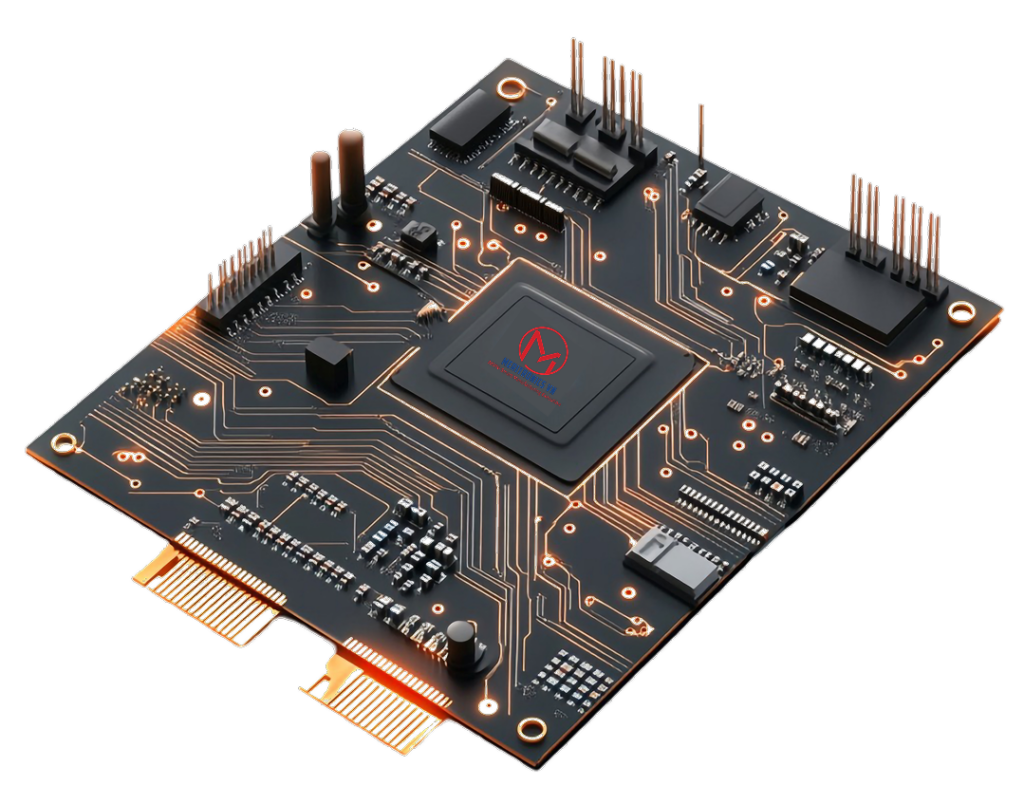

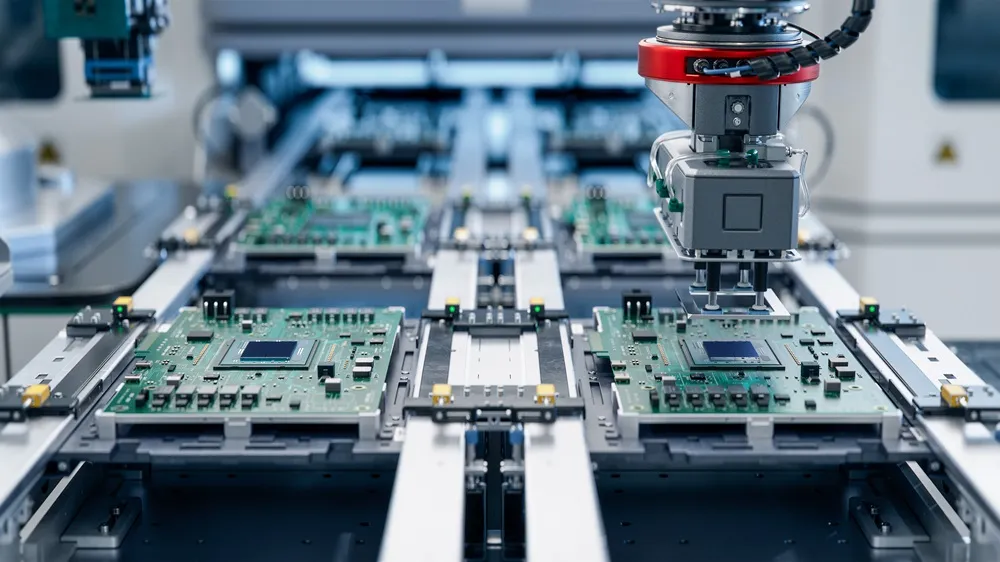

Meritronics is a trusted provider of high-quality PCBA assembly services. We specialize in both full turn-key and partial turn-key solutions to meet the unique needs of our clients.

With our full turn-key service, we manage the entire production process — from PCBA fabrication, sourcing of 100% original components, assembly, functional testing, to final product integration — all under strict quality control.

For clients who opt for partial turn-key services, we offer flexibility by allowing them to supply their own PCBAs or specific components, while we handle the remaining stages with the same commitment to excellence.

We offer high-volume manufacturing services with strict quality control to ensure consistent and reliable products

Our team develops embedded software, mobile apps, and backend systems to bring your hardware to life.

From concept to schematic and PCB layout, we design optimized hardware solutions tailored to your project’s needs.

We handle the entire process—from design to delivery—so you can focus on your business while we build your product.

Our team consists of seasoned engineers and developers with years of experience across various industries. We manage the full product lifecycle — from ideation to mass production — under one roof.

We have manufactured many thousands of products with a strict quality control process.

Every item is carefully inspected before reaching our customers.

With over 5 years of experience, we’ve gained in-depth industry knowledge.

Real-world expertise allows us to solve complex challenges efficiently.

Our customer satisfaction rate reaches 99% after using our services.

We constantly listen and improve to serve you better every day.

PCBA stands for Printed Circuit Board Assembly, which refers to the process of attaching electronic components onto a PCB (Printed Circuit Board) to create a functional electronic device.

The PCBA manufacturing process involves soldering components such as resistors, capacitors, ICs, and connectors onto the PCB using advanced techniques like SMT (Surface Mount Technology) and THT (Through-Hole Technology).

Mass production is the process of manufacturing large quantities of products at low cost and high speed.

This requires optimized manufacturing processes to minimize both cost and production time.

Software development is the process of designing, programming, testing, and maintaining software applications.

The goal is to create high-quality software solutions that meet user needs.

Hardware design is the process of creating blueprints and plans for electronic devices, including circuit boards, components, and connections.

This is a crucial step in ensuring the device’s effective and long-lasting performance.

Full turnkey refers to a service that provides everything from design to manufacturing and deployment of the final product, where the customer simply needs to “turn the key” to use it.

This ensures completeness and saves time for the customer.

We’re here to support, collaborate, and grow with you.

Reach out and let’s start the conversation.